DC Inverter Technology, IGBT Module Plasma Cutting MachineLGK-130 LGK-160

Product Features Description

Our plasma cutting machines use advanced IGBT high-frequency inverter technology to ensure high efficiency and lightweight design.

It is designed to handle high load durations, making it suitable for long cutting operations. The non-contact high-frequency arc starting function ensures high success rate and minimal interference.

In addition, the machine also provides precise stepless cutting current adjustment to adapt to different thicknesses. Features excellent arc stiffness, ensuring smooth cuts and excellent cutting performance.

The slow rise of arc cutting current minimizes impact and reduces damage to the cutting tip. The machine also has wide grid adaptability, providing stable cutting current and consistent plasma arc.

Its humanized and beautiful design enhances the convenience of operation. To ensure durability and reliability, key components are reinforced with triple protection mechanisms, allowing the machine to adapt to various harsh environments. This ensures stable and reliable operation.

Manual Arc Welding

Inverter Energy Saving

IGBT Module

Air Cooling

Three-Phase Power Supply

Constant Current Output

Product Specification

|

Product Model |

LGK-130 |

LGK-160 |

|

Input Voltage |

3-380VAC |

3-380V |

|

Rated Input Capacity |

20.2KVA |

22.5KVA |

|

Inverting Frequency |

20KHZ |

20KHZ |

|

No-Load Voltage |

320V |

320V |

|

Duty Cycle |

80% |

60% |

|

Current Regulation Range |

20A-130A |

20A-160A |

|

Arc Starting Mode |

High frequency non-contact ignition |

High frequency non-contact ignition |

|

Power cooling system |

Forced air cooling |

Forced air cooling |

|

Cutting gun cooling method |

Air cooling |

Air cooling |

|

Cutting Thickness |

1~20MM |

1~25MM |

|

Efficiency |

85% |

90% |

|

Insulation Grade |

F |

F |

|

Machine Dimensions |

590X290X540MM |

590X290X540MM |

|

Weight |

26KG |

31KG |

Arc Welding Function

The plasma cutting machine is a precise and efficient metal cutting equipment. It uses a plasma arc to generate intense heat, which is directed through a nozzle to the cutting point. This process effectively cuts the metal material into the required shape, ensuring the accuracy and efficiency of the cutting process.

Plasma cutting machine has the following functions:

High precision cutting: Plasma cutters utilize a high-energy plasma arc to achieve precise metal cutting. It can cut complex shapes quickly while ensuring the flatness and precision of the cutting edge.

High efficiency: Plasma cutters have impressive cutting speeds and excellent work efficiency. It is good at cutting various metal materials quickly, thereby increasing production efficiency and reducing working time.

Wide cutting range: Plasma cutters are versatile and can easily cut through various thicknesses and types of metal materials, including carbon steel, stainless steel, and aluminum. Its cutting ability is not affected by the hardness of the material, allowing it to effectively handle a variety of cutting tasks.

Automation control: Plasma cutting machines in today's era are usually equipped with automated control systems that can effectively automate the entire cutting process. This automation not only improves work efficiency but also improves the overall quality of the final product.

Safety performance: The plasma cutting machine is equipped with a series of safety measures such as overheating and overload protection.These measures are to protect operators and equipment.

In general, the plasma cutting machine is a high-precision and high-efficiency metal cutting equipment. It is widely used in manufacturing, construction and other fields, and can meet the needs of various metal material cutting.

Application

For cutting carbon steel/ stainless steel/ aluminum/ copper and other industries, sites, factories.

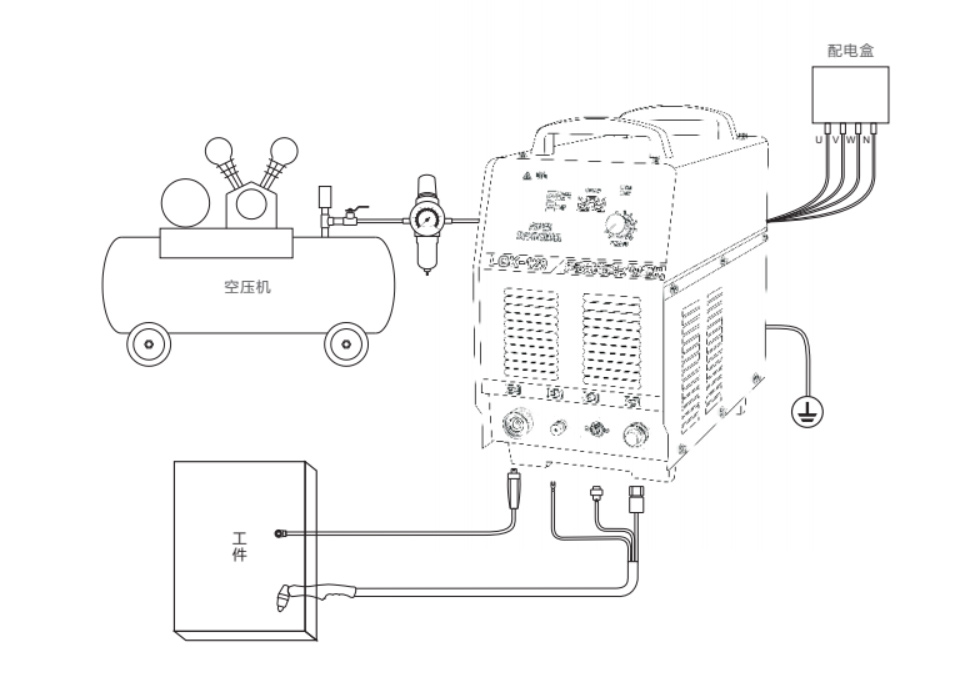

Installation Precautions

Input voltage: 3 ~ 380V AC±10%, 50/60Hz

Input cable: ≥8 mm², length ≤10 meters

Distribution switch: 100A

Output cable: 25mm², length ≤15 meters

Ambient temperature: -10 ° C ~ +40 ° C

Use environment: the inlet and outlet can not be blocked, no sunlight direct exposure, pay attention to dust